Reformers

In principle, a PEM fuel cell operates like a battery, but unlike a battery, it will produce electricity and heat as long as fuel (hydrogen) is supplied. In order to produce purified hydrogen from various hydrocarbon fuel sources, steam methane reforming (SMR) has been used for the better part of a century to make hydrogen from natural gas, and is conventionally performed in fixed catalyst beds. All SMR catalysts are poisoned by sulfur and carbon deposition (coke) when liquid hydrocarbons are reformed, and the fouling is faster when heavy fuels such as JP-8 are used. These liquid fuels cause irreversible catalyst fouling with no method of regenerating the catalyst.

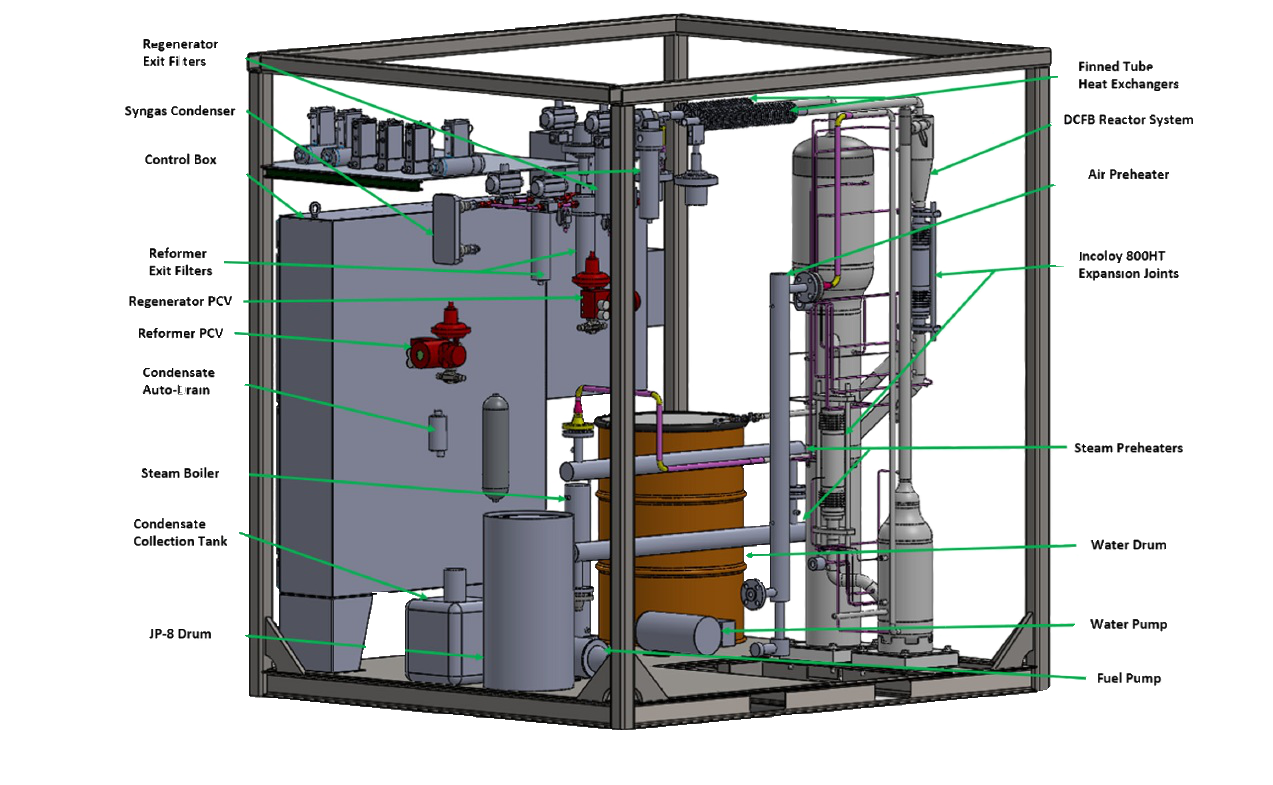

TDA Research has recently built and demonstrated a laboratory-scale, dual circulating fluidized bed (DCFB) reactor system to continuously steam reform heavy oils and JP-8 using a commercial catalyst while simultaneously regenerating the catalyst. The syngas from our process contains approximately 70 vol% H2 (dry basis), and thus, must be followed by downstream processes (water gas shift and H2 purification using pressure swing adsorption) to ensure high hydrogen purity for fuel cell applications. Our patented technology generates hydrogen from multiple fuel sources using our currently-under-construction Multi-Fuel Reformer skid-mounted unit for the initial reforming step.

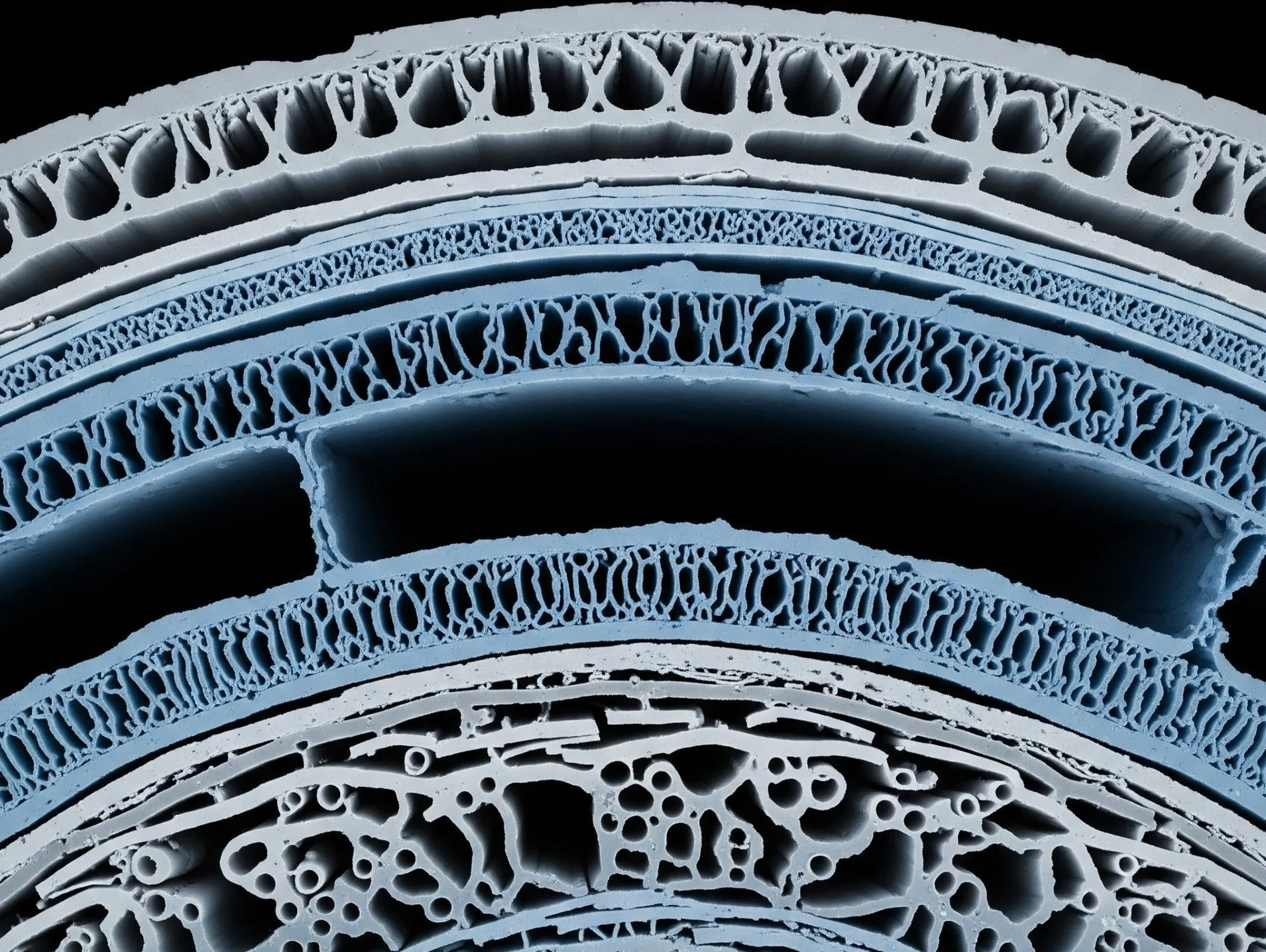

TDA’s membrane design for the separation of hydrogen. In addition to enabling fuel cells to run on a wide variety of both clean and dirty fuels, they provide the U.S. chemical and petrochemical industry with cost effective methods for carrying out hydrogen separations.

Compact and ruggedized membrane reactor-methanol reformer

Highly effective methanol reforming catalyst

Excellent robustness

Provides high gas throughput

High separation and selectivity