Seawater Sensor

To protect against corrosion, a ship’s Impressed Current Cathodic Protection (ICCP) system distributes electrical energy between sections of the hull. The ICCP control system measures voltages using seawater silver/silver-chloride reference electrodes and adjusts the electrical potentials appropriately. Because changes in seawater chemistry near the hull will change the electrical potentials, there is a need for real-time oceanographic measurements that the ICCP can use to provide feedback control to the ICCP.

A new generation of measurement technology is being developed that use new, ultra-compact, ultra-reliable, low-power sensors with accuracy traceable to U.S. NIST standard measurements. These new microelectromechanical systems (MEMS) technologies offer an opportunity for the submarine community to access and utilize environmental data (oceanographic measurements) on the outer hull of a submarine. However, these sensors have not been ruggedized to reliably function in this harsh environment, and it is the objective of this project to develop and build such a sensor.

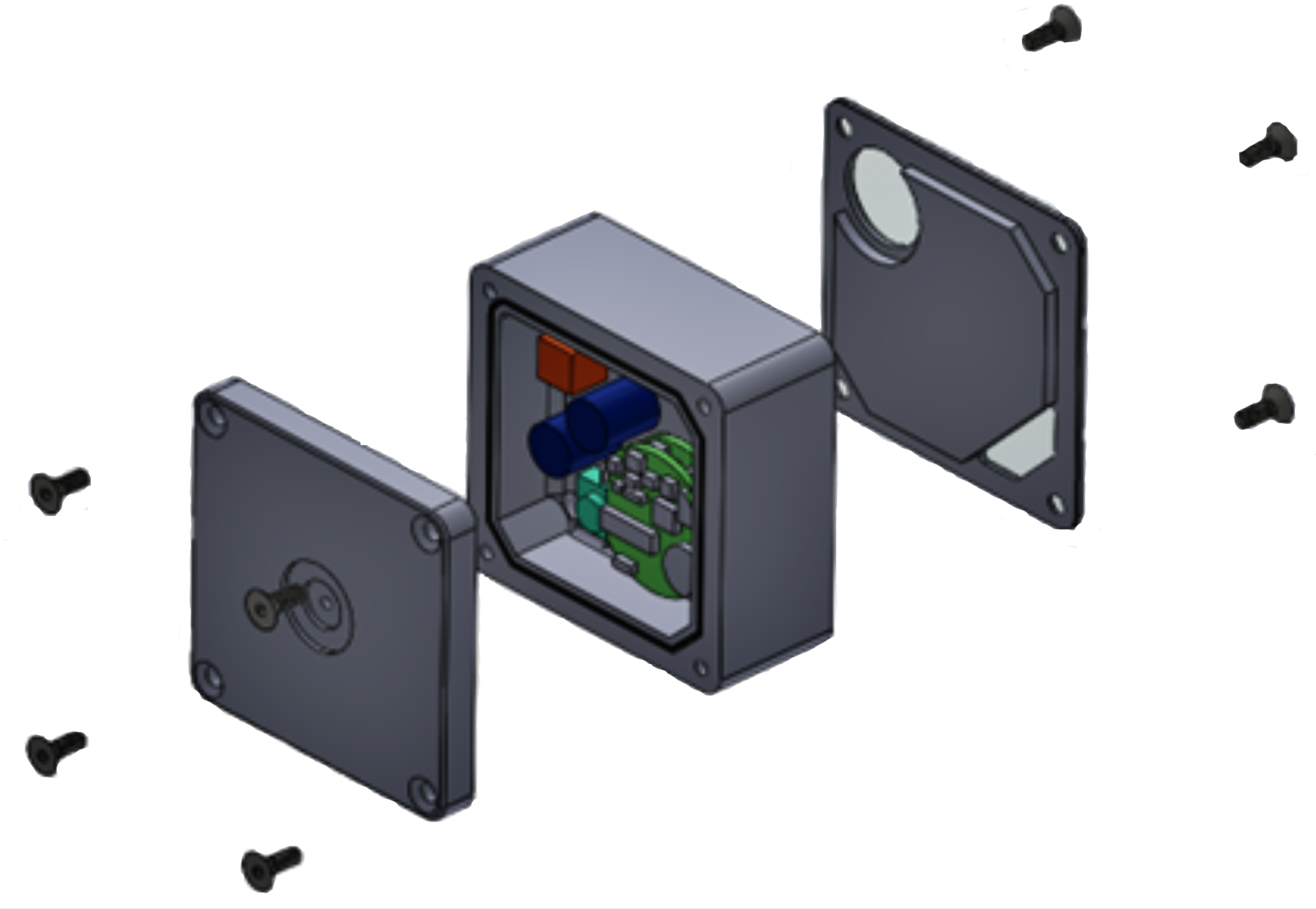

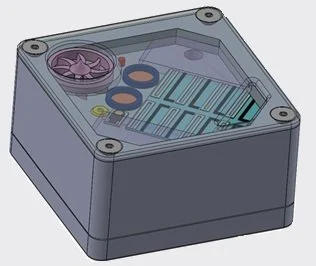

TDA has developed a concept and design for a chip-scale oceanographic sensor that can be integrated onto a ship, submarine, or unmanned underwater vehicle (UUV) hull to accurately measure ocean water chemistry in real-time. TDA’s design involved solid state devices including miniaturized electrodes, control circuitry, and sensors that are affordable and can be mass produced with screen printed manufacturing techniques. Our sensor device (3” x 3” x 1.7”) will make highly accurate measurements of T, pH, conductivity, TDO (total dissolved oxygen), as well as chloride, sodium, calcium, and other relevant ions. Physically, we have designed our unit to be like the current ICCP electrode housings used on Virginia Class Submarines. The overall objective is to create a chip scale sensor that integrates the threshold oceanographic chemical parameter measurements into a single device without interfering with the reference electrodes used in ICCP system. Our design fits in a robust, small footprint package that will feature a sampling system that prevents biofouling and solid-state sensor technologies that can withstand the required temperature and pressure swings. The sample chamber is equipped with an impeller and ultrasonic transducer that are used to prevent accumulation of dirt, debris and particulates, which should help prevent biofilm formation. We will also apply antimicrobial coatings that should mitigate biofilm accumulation in areas which cannot be cleaned by the impeller and the ultrasound, such as the outer surfaces of sensor housing, insides of the sample chamber (other than the active sensor area).

Can be integrated onto a ship, submarine, or unmanned underwater vehicle (UUV) hull to accurately measure ocean water chemistry in real-time.

Measures temperature, conductivity and dissolved oxygen in seawater at depth.

Includes sensor measurements for other seawater ions.

Affordable and easily mass produced.

Sensor Size: 3” x 3” x 1.7”

Highly accurate measurements of T, pH, conductivity, TDO (total dissolved oxygen), as well as the concentrations of chloride, sodium, calcium, and other relevant ions.